You might wonder, is the application of AI in supply chain management only pertinent to large enterprises with gargantuan budgets? The answer is that AI technologies have become more accessible, enabling organizations of varying sizes to tap into the power of data-driven insights. By the time you finish reading, we hope you’ll feel more confident about AI in supply chain management and ready to explore these tactics in your own organization.

1. Cost Reduction

Cost reduction remains one of the core benefits of AI in supply chain management. Companies are constantly searching for methods to reduce operating costs, and AI-based solutions can help. Predictive analytics tools, for example, examine past data to find wasteful spending on things like overstocking, monotonous work, or inefficient inventory control procedures. These algorithms lessen the need for businesses to maintain significant amounts of excess inventory by improving their ability to predict demand patterns.

Let’s use a straightforward example to demonstrate. Assume a mid-sized clothing store uses a monthly shipping schedule to deliver goods from its main warehouse to several distribution hubs. The merchant can quickly identify differences in delivery requirements by implementing an AI system that detects abnormalities in order volumes. As soon as an anomaly is detected, the system might reduce an unnecessary shipment, saving considerable logistics costs.

One less obvious consideration when focusing on cost reduction is the need for consistent data quality. AI solutions crave clean, complete datasets to produce solid insights. If you’re relying on messy legacy systems, you’ll want to invest time in data preparation before expecting the software to generate accurate predictions. This data cleansing process can feel tedious but it’s absolutely vital.

Moreover, a practical tip based on real-world experience is to start small. Launch a pilot program on one or two nodes in the supply chain. Perhaps focus on a particular warehouse or a specific region. By measuring cost improvements at a small scale, you can demonstrate the value of an AI-driven approach and then expand.

2. Improved Forecasting Accuracy

The next big advantage of AI in logistics and supply chain management is enhanced forecasting accuracy. Let’s face it, supply chain leaders often struggle to predict demand with traditional methods. Human guesswork, which might once have been enough, quickly pales in comparison to machine learning systems that can process millions of data points with lightning-fast precision.

Take the application of AI in supply chain management for demand planning as a tangible example. A food and beverage manufacturer might rely on AI-driven forecasting to handle seasonal spikes in consumer interest. Rather than produce cookies year-round at the same rate, advanced AI forecasting might predict that sales will spike by 20 percent during summer months and fall by 10 percent in winter. These insights allow the producer to adjust production, preventing both overstock and understock scenarios. The result is minimized waste, happier customers, and a kinder bottom line.

You might also see specialized AI vendors offering tools that factor in external data such as weather, consumer sentiment, or economic indicators. This is especially critical if your supply chain is complex, spanning multiple regions with vastly different market conditions. Everyone hates losing money due to “overly optimistic” guesswork, so a robust forecasting algorithm mitigates these risks.

Yet, there’s a potential implementation challenge here: cross-department alignment. Forecasting touches almost every business function, from sales to finance. Ensuring that all departments collaborate and trust AI-driven predictions can be tricky, especially if your team is accustomed to gut feeling. However, once everyone sees the data-backed results, it becomes much easier to unify processes around accurate forecasts.

3. Enhanced Operational Efficiency

Next on our list of the top benefits of AI in supply chain management is the profound boost in operational efficiency. By operational efficiency, we’re talking about how well a company’s resources (people, equipment, raw materials) are used to achieve maximum output. When you integrate AI for supply chain management into your operations, you can strategically automate labor-intensive tasks, optimize asset usage, and dynamically plan for resource availability.

Consider a global electronics manufacturer with multiple assembly lines. An AI system that monitors machine workloads and throughput data can automatically schedule maintenance before a costly breakdown occurs. Even small windows of predictive maintenance can avert downtime that might otherwise cost the firm millions. In supply chain terms, it translates to fewer disruptions and fewer frantic phone calls to expedite missing parts.

Another prime example includes route optimization. Delivery fleets can be dynamically rerouted based on real-time traffic data, thereby ensuring drivers take the least congested route. And if a truck breaks down, the AI engine might instantly reroute other vehicles to handle urgent shipments. This kind of agility was once unthinkable but is now quite feasible thanks to the deep insights that machine learning can deliver.

However, achieving high operational efficiency sometimes involves rethinking job roles. Some employees might worry about “robots taking over,” but in reality, AI in logistics and supply chain management often frees workers from mundane tasks, enabling them to focus on higher-value activities. The automation of certain processes might actually lead to staff members tackling more strategic problem-solving. It is worth communicating these changes early and clearly so that everyone feels part of the transformation, instead of left behind.

4. Reduced Lead Times

Reduced lead times are a stellar outcome of intelligent supply chains. Imagine the entire end-to-end process running seamlessly, without long delays at any step. AI in supply chain management can zero in on bottlenecks, whether they occur in sourcing raw materials or shipping products to storefronts. Let’s break down four ways AI shortens these timelines:

- Warehouse Automation: Robotic picking systems powered by AI can move items faster than manual labor alone. By tracking every item’s location and prioritizing based on shipping schedules, lead times shrink.

- Real-Time Data Analysis: AI systems continuously monitor performance metrics, so if a part of the chain lags, managers get alerted. For instance, noticing that a particular shipping route is slower than predicted prompts immediate reallocation of resources.

- Smart Contract Execution: In more advanced setups, AI works in tandem with blockchain-based smart contracts to automate payments and order fulfillments in near real-time. If materials arrive on schedule, the transaction triggers automatically, saving days of back-and-forth paperwork.

- Dynamic Supplier Selection: AI can quickly analyze multiple suppliers on parameters like delivery reliability, quality, and cost. This means no more repeated guesswork in supplier selection, and fewer nasty surprises at the last minute.

But watch out for intangible factors that can still slow you down. For instance, local regulations or trade policies might cause supply chain hiccups. Although an AI algorithm can’t magically remove licensing headaches, it can highlight potential delays early, giving you time to respond. In our experience, companies that integrate AI for supply chain management typically see lead-time improvements of 10 to 25 percent, but real numbers vary based on baseline efficiency and the complexity of processes.

5. Scalability and Flexibility

Finally, organizations looking to future-proof themselves will find that the application of AI in supply chain management easily scales with growth. Traditional supply chain processes can become unwieldy when you expand into new markets or launch new product lines. AI, in contrast, adapts to the increasing volumes of data and complexity with relative ease.

One reason for this adaptability is the modular nature of many AI solutions. You can plug in additional capabilities, such as advanced analytics or machine vision for quality control, without having to rebuild your systems from scratch. Imagine a scenario in which you decide to open new distribution centers in different countries. Instead of redoing your entire supply chain planning manually, your AI-driven platform would incorporate new data sets like local demand patterns, currency fluctuations, and shipping regulations.

Plus, the learning aspect never ceases. The more data your system processes, the sharper the insights become. This is particularly relevant in e-commerce, where consumer demand can be unpredictable. AI-driven solutions learn from every transaction, refining their models to predict future demand more accurately. The result is an agile, scalable supply chain architecture that can handle both steady-state operations and sudden growth spurts.

Of course, this all hinges on solid infrastructure. Cloud-based platforms often suit AI systems well because they can expand computing resources quickly and more cost-effectively than in-house servers. The tradeoff is that businesses must trust a third-party provider with their data. And that’s where data security enters the conversation, a topic that might not always be top-of-mind but is absolutely critical when scaling your operations rapidly. If you compromise on security measures, the newfound agility might come at the expense of data privacy risks.

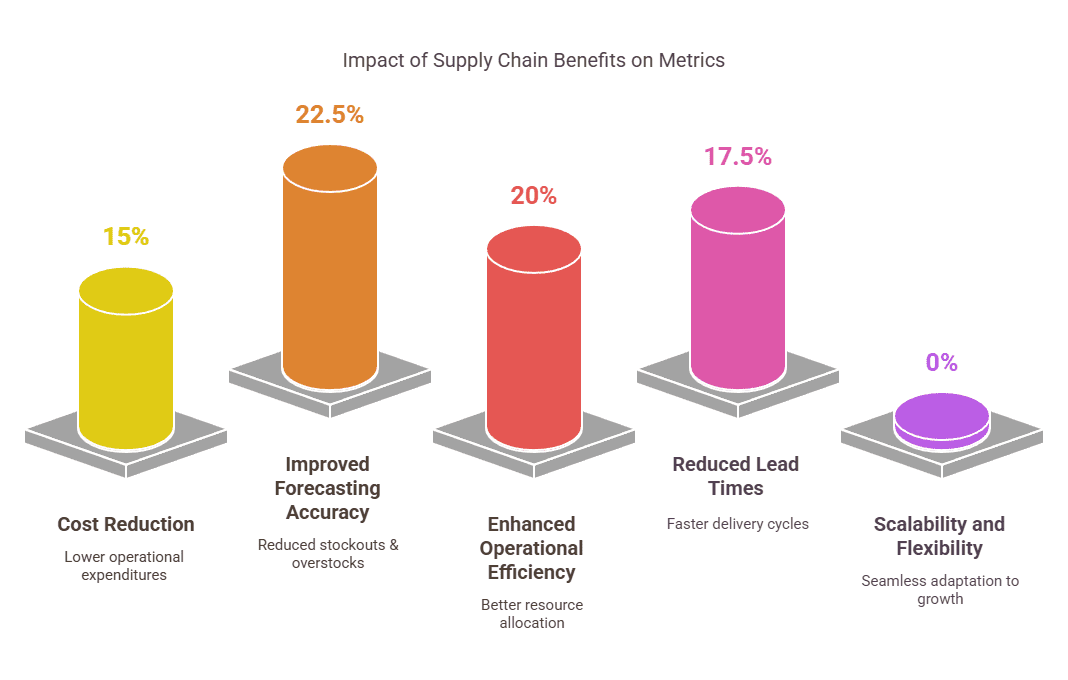

Comparative Overview of Key Benefits

Below is a quick data table that summarizes how each of the five benefits typically impacts different supply chain metrics. While results differ from one organization to another based on scale and complexity, this table provides a straightforward bird’s-eye view:

| Benefit | Primary Impact | Example Metric Improvement |

|---|---|---|

| Cost Reduction | Lower operational expenditures | Up to 15% decrease in logistics costs |

| Improved Forecasting Accuracy | Reduced stockouts & overstocks | 20-25% increase in forecast accuracy |

| Enhanced Operational Efficiency | Better resource allocation | Up to 20% increase in productivity |

| Reduced Lead Times | Faster delivery cycles | 10-25% shorter order-to-delivery span |

| Scalability and Flexibility | Seamless adaptation to growth | Faster rollouts in new markets |

Each of these benefits underlines why AI in supply chain management has garnered so much attention in recent years. If you have ambitions for global expansion, or you simply want to run a tighter ship locally, these improvements can radically shift your bottom line and competitive posture.

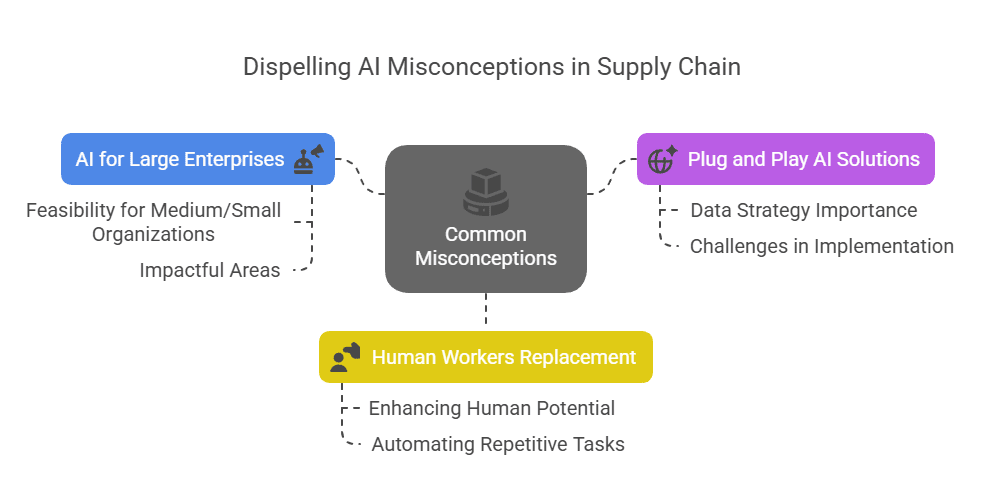

Common Misconceptions

Before we wrap up our list, let’s dispel a few myths:

- “AI only works for huge, tech-savvy enterprises.”

Not true. While big enterprises often have more resources, AI in logistics and supply chain management has become increasingly feasible for medium and smaller organizations. Start by focusing on the single area that offers the most noticeable impact, whether that’s inventory management or demand planning. - “You can just ‘plug and play’ AI solutions.”

AI, especially sophisticated machine learning models, requires discipline in data collection, cleaning, and governance. A robust data strategy is vital, and failing to set one up can undermine the entire project. - “Human workers will be replaced.”

In practice, AI for supply chain management often boosts human potential by automating repetitive tasks. This frees employees to solve higher-level strategic issues that AI can’t handle alone.

A Mild Digression on Data Security

I’d like to refine one earlier point: data security can’t be an afterthought. While it might not be the first topic that comes to mind when exploring the benefits of AI in supply chain management, it can turn upside-down if properly neglected. Sensitive customer details, supplier contracts, or shipping routes might become prime targets for cybercriminals. Ensuring robust encryption, authentication measures, and compliance with international data protection norms like GDPR is essential to protect both your operations and your reputation.

Indeed, data security forms part of the broader puzzle that is AI in supply chain management. A well-protected environment fosters trust internally and externally, enabling you to reap the full benefits of automation and analytics without risking a breach that could cause massive disruptions.

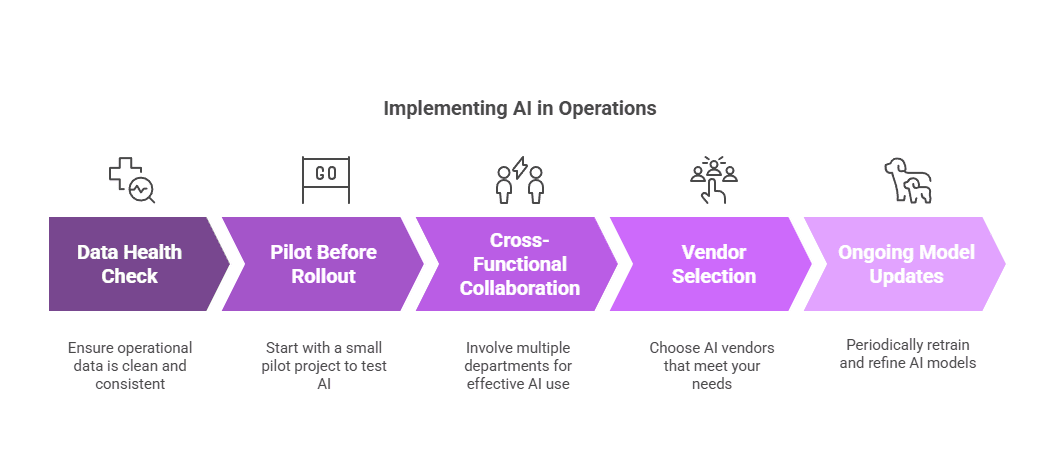

Practical Implementation Tips

Now that we’ve covered the major benefits, let’s get more practical.

- Data Health Check: Ensure your operational data is clean, consistent, and as detailed as possible. If you skip this step, your AI results might be skewed or incomplete.

- Pilot Before Rollout: Start with a small pilot project. Maybe you address cost reduction within a single warehouse or region. See how AI performs on limited terrain, then scale.

- Cross-Functional Collaboration: Demand forecasting, for example, should involve sales, marketing, and finance for maximum effectiveness. AI outputs can only be as good as the organizational alignment supporting them.

- Vendor Selection: AI solutions come in different flavors. If building an in-house data science team seems impractical, consider reputable vendors that have proven solutions. Just be sure their approach aligns with your data privacy requirements.

- Ongoing Model Updates: Once you deploy AI, the job isn’t done. Periodically retrain and refine models for changing consumer trends, external economic shifts, or new product lines.

One More Clarification

Earlier, we discussed potential hurdles like legacy systems and cross-departmental alignment. Actually, these challenges underscore the need for strategic planning. An AI initiative without organizational buy-in will struggle to gain traction, even if the technology itself is top-notch. This means you need to plan for internal training sessions and transparent communication to ensure everyone understands what the AI tool does, why you’re using it, and how it will transform their workflows.

Conclusion and Next Steps

In sum, the application of AI in supply chain management can yield measurable benefits across virtually every operational dimension. We’ve delved into cost reduction, improved forecasting accuracy, enhanced operational efficiency, reduced lead times, and the overall scalability that AI technology supports. We explored actual examples like predictive maintenance, dynamic route optimization, and anomaly detection in shipping volumes. We also touched on lesser-known considerations such as data security and the importance of data governance.

By harnessing AI in logistics and supply chain management effectively, businesses can transform archaic and reactive processes into a modern, proactive framework. While implementation requires some upfront investment in technology, data quality, and organizational readiness, the returns often include stronger competitive positioning and substantial bottom-line improvements.

So where do we go from here? If you’re intrigued by AI for supply chain management and want to explore the possibilities further, consider a small pilot program to demonstrate its viability. Watch the metrics and track your success closely. And of course, stay curious about how your data is structured and protected. With the right strategy in place, AI can become a reliable partner for growth, resilience, and innovation in whatever sector your supply chain serves.

About Blocktech Brew

At Blocktech Brew, we specialize in next-generation technology solutions, from implementing AI in supply chain management to developing secure blockchain applications. Our team of experts is dedicated to helping businesses of all sizes leverage innovative solutions that solve real-world problems, whether you’re streamlining logistics or tokenizing assets.

We’d love to hear from you and learn about the challenges you face in your operations. If you’re ready to explore how AI can transform your supply chain processes, don’t hesitate to reach out. Our proven methodologies and experienced professionals will guide you every step of the way, ensuring that your transformation is smooth, secure, and primed for sustainable success.